.jpg?x-oss-process=image/resize,h_400,m_lfit/format,webp)

Selecting the appropriate sesame oil pressing method is crucial for businesses in the food, health supplement, and cosmetics industries. This guide comprehensively analyzes the two main pressing processes - cold pressing and hot pressing, to assist enterprises in making informed decisions based on their production needs.

Cold pressing is a method that extracts oil at low temperatures, typically below 60°C. This gentle process preserves the natural flavor and nutritional components of sesame seeds. It retains high levels of antioxidants such as vitamin E and sesamol, which are beneficial for health. For example, cold - pressed sesame oil has been shown to contain up to 30% more vitamin E compared to hot - pressed oil in some studies.

.jpg)

Cold Pressing Advantages:

On the other hand, hot pressing involves heating the sesame seeds to higher temperatures, usually between 120 - 180°C. This process increases the oil yield significantly, sometimes up to 80 - 90% of the total oil content in the seeds. However, the high temperature can cause some loss of nutrients and change the flavor profile, resulting in a more intense and pungent taste.

Hot Pressing Advantages:

Temperature is a critical factor in both cold and hot pressing processes. In cold pressing, precise temperature control is necessary to ensure that the oil retains its nutritional value. A temperature rise above 60°C can start to degrade the antioxidants and other sensitive components. In hot pressing, the temperature range determines the oil's flavor intensity and the degree of nutrient loss. For instance, a temperature of 120 - 140°C may produce a moderately flavored oil with relatively less nutrient loss compared to 160 - 180°C.

For small - scale producers, cold pressing is often a preferred choice. It requires less capital investment in equipment and is suitable for producing high - end, niche products targeting health - conscious consumers. The lower production volume can be compensated by the higher profit margins associated with premium cold - pressed oils.

Medium - scale enterprises may need to balance between oil yield and quality. They can consider using both cold and hot pressing methods. For example, they can produce a certain proportion of cold - pressed oil for the high - end market and hot - pressed oil for more price - sensitive customers or for use in processed products.

Large - scale producers usually opt for hot pressing due to its high oil yield and cost - effectiveness. With advanced technology, they can also minimize nutrient loss and control the flavor profile to meet market demands. For example, some large - scale factories use multi - stage hot pressing with precise temperature control to improve product quality.

The sesame oil production industry is constantly evolving with new technologies. For example, new cold - pressing equipment with better temperature control systems can improve the efficiency of cold pressing and further enhance the quality of cold - pressed oil. In hot pressing, advanced heating technologies can reduce the negative impact of high temperatures on nutrients.

Some factories are also using enzymatic pre - treatment methods before pressing. Enzymes can break down the cell walls of sesame seeds, increasing the oil yield in both cold and hot pressing processes. This method has been shown to increase the oil yield by 5 - 10% in some experiments.

Choosing the right sesame oil pressing method is a complex decision that depends on various factors such as production scale, product positioning, and market demand. By understanding the characteristics of cold and hot pressing, temperature control, and the latest technological trends, businesses can make more informed choices to improve production efficiency and product quality.

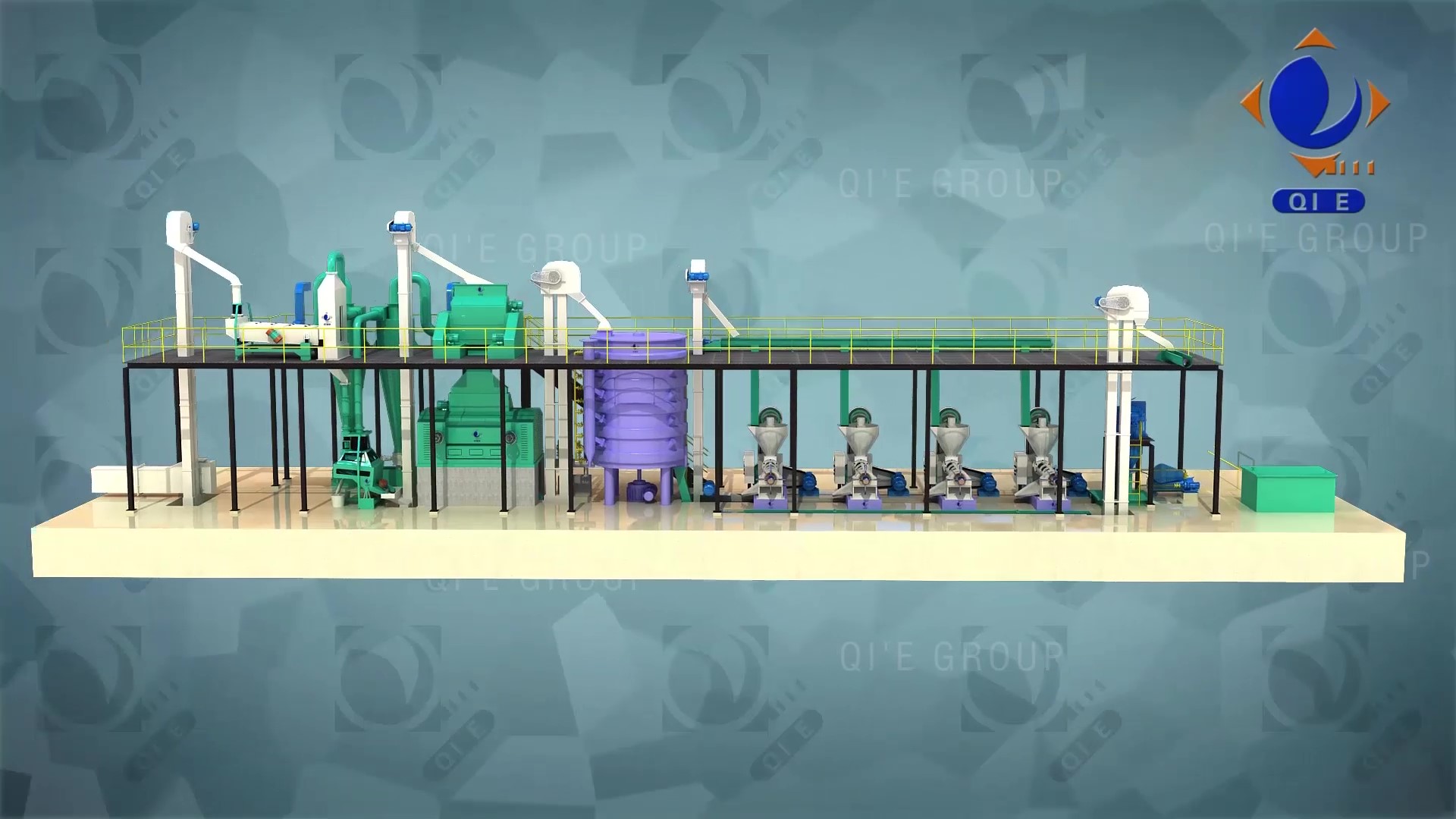

Learn about the sesame oil pressing equipment suitable for your production scale