You may wonder what exactly the cold and hot pressing processes of sesame oil entail. Cold pressing is a method where sesame seeds are pressed at a relatively low temperature, typically below 60°C. This process is known for its gentle treatment of the seeds, which helps preserve the natural nutrients and delicate flavors of the sesame oil. On the other hand, hot pressing involves heating the sesame seeds to a higher temperature, usually around 120 - 180°C before pressing. This process can increase the oil yield but may have an impact on the nutritional value and aroma of the oil.

Let's take a closer look at how these two processes affect the aroma and nutritional components of sesame oil. Cold - pressed sesame oil retains more of the natural aroma of sesame seeds, offering a more delicate and pure fragrance. In terms of nutritional value, cold - pressed oil is rich in unsaturated fatty acids, which can account for up to 80% of the total fat content, and vitamin E, with an average content of about 50 - 80 mg/kg. These nutrients are beneficial for human health, such as reducing cholesterol levels and protecting cells from oxidative damage.

Hot - pressed sesame oil, however, has a stronger and more intense aroma due to the Maillard reaction during the heating process. But the high - temperature treatment may cause some loss of nutritional components. For example, the content of unsaturated fatty acids may decrease to around 70 - 75%, and the vitamin E content may drop by about 20 - 30% compared to cold - pressed oil.

| Process | Aroma | Unsaturated Fatty Acids | Vitamin E |

|---|---|---|---|

| Cold Pressing | Delicate and pure | Up to 80% | 50 - 80 mg/kg |

| Hot Pressing | Strong and intense | 70 - 75% | 20 - 30% less than cold - pressed |

When it comes to different production scales, the choice of pressing method is crucial. For small - scale production, cold pressing is often a good choice. It requires less investment in equipment and is suitable for producing high - quality, artisanal sesame oil. For example, a small - scale producer with an annual output of less than 100 tons may find that cold - pressing equipment can meet their needs, allowing them to focus on the niche market of high - end, healthy sesame oil.

Medium - scale producers, with an annual output ranging from 100 - 500 tons, may consider a combination of cold and hot pressing. They can use cold - pressing for a portion of their production to meet the demand for high - quality oil, while using hot - pressing for the rest to increase the overall output and meet the market's diverse needs.

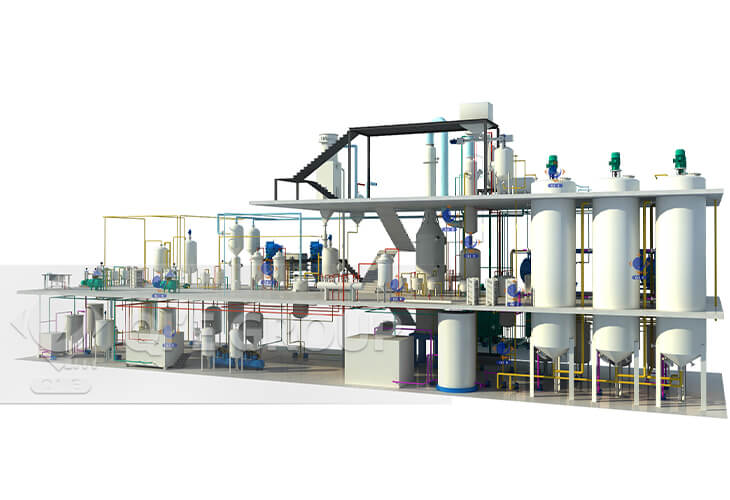

Large - scale producers, with an annual output of over 500 tons, may lean towards hot - pressing due to its higher oil yield and efficiency. However, they also need to pay attention to the quality control and nutritional preservation. For instance, some large - scale producers are now using advanced technologies to optimize the hot - pressing process and minimize the loss of nutrients.

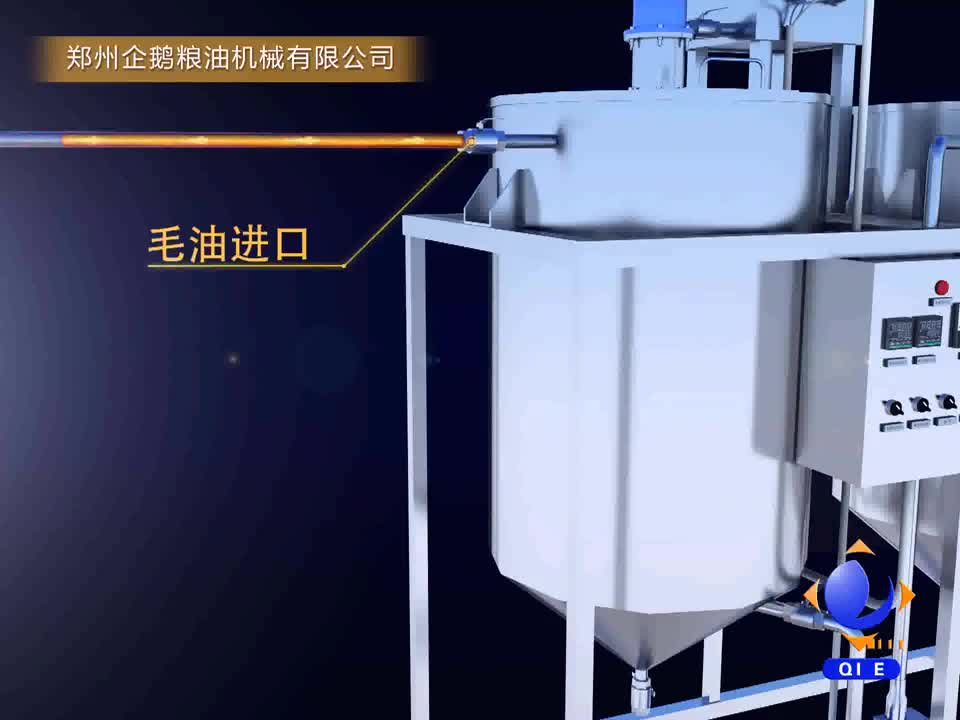

The sesame oil production industry is constantly evolving, with the introduction of new technologies. Automation control systems are becoming more and more popular, which can precisely control the temperature, pressure, and other parameters during the pressing process, ensuring consistent product quality. Energy - saving and environmental - friendly technologies are also being widely adopted. For example, some new equipment can reduce energy consumption by up to 30% and minimize the environmental impact through improved waste treatment.

When choosing the right sesame oil pressing equipment, you need to consider several factors. Your product positioning is crucial. If you aim to produce high - end, healthy sesame oil, cold - pressing may be more suitable. Your target market also plays an important role. Some markets may prefer the delicate aroma of cold - pressed oil, while others may favor the strong flavor of hot - pressed oil. Additionally, your cost budget is a key consideration. Cold - pressing equipment may have a lower initial investment but a higher production cost per unit, while hot - pressing equipment may require a larger upfront investment but offer a lower cost per unit in large - scale production.

By carefully considering these factors, you can make a more informed decision and choose the sesame oil pressing equipment that best suits your needs. Our solutions can precisely match your production requirements, ensuring that every drop of sesame oil is truly valuable.