“Consistent product quality stems from precise equipment selection, optimized operation, and strict maintenance — the pillars to reduce cost and raise production efficiency in sesame oil manufacturing.”

Selecting the ideal sesame oil pressing machine significantly influences product quality and cost efficiency. As a factory manager, your first consideration should be matching the machine’s production capacity with your factory’s output demands. Medium to large-scale equipment typically handles 500kg to 2000kg of sesame seed input per hour, with output proportional to raw material volume and processing parameters.

Automatic vs. semi-automatic systems present different trade-offs. Fully automated machines, while attracting higher upfront investments (typically 10-20% more), assure stable pressing temperature, continuous feeding, and integrated quality control, which reduces operator errors that cause product variation. However, for factories optimizing operational costs, semi-automated models provide flexibility with simplified maintenance and lower energy consumption.

| Machine Type | Capacity (kg/hr) | Automation Level | Typical Power Consumption (kW) | Approx. ROI (Months) |

|---|---|---|---|---|

| Medium-Scale Manual | 500-800 | Low | 5-7 | 10-12 |

| Large-Scale Semi-Automated | 800-1500 | Medium | 8-12 | 8-10 |

| Large-Scale Fully Automated | 1500-2000+ | High | 12-18 | 6-8 |

Optimal operation requires detailed knowledge of the running workflow and acknowledgment of key factors affecting output quality. For instance, the choice between cold pressing and hot pressing influences both flavor profiles and oil yield. Cold pressing preserves aroma and nutritional value, typically yielding 8-10% oil, while hot pressing can increase yield up to 15% but may cause slight degradation of delicate compounds.

Pre-treatment of sesame seeds such as cleaning, dehulling, and controlled roasting further impacts the extraction efficiency. For example, proper roasting at 120-130°C for 15-20 minutes can improve oil release and flavor without compromising quality.

Key operational tips include:

A mid-sized sesame oil plant in Egypt optimized their pressing schedule by integrating an automated temperature control system, reducing oil yield variability from ±5% to under 2%. This enhancement decreased total annual maintenance costs by 20%, while boosting net oil output by approximately 7%.

Preventative maintenance is the backbone of sustained machine performance. Routine steps include:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning Press Chamber & Screens | Daily | Prevents clogging and contamination, improves oil quality |

| Lubrication of Moving Parts | Weekly | Reduces wear and tear, extends equipment life |

| Inspection for Screw & Barrel Wear | Monthly | Maintains efficiency and prevents unexpected breakdowns |

| Machine Calibration & Control Check | Quarterly | Ensures process consistency and product stability |

Incorporating a digital logbook for operators to record deviations, maintenance actions, and outcomes fosters accountability and helps identify recurring issues early. Factories that adopt such systems report up to 15% reduction in maintenance downtime.

Inconsistent sesame oil quality is often traced back to improper equipment usage or overlooked maintenance. By standardizing operation protocols and optimizing pressing parameters, your plant can achieve oil quality consistency above 95%, a key metric for sustaining market competitiveness.

Moreover, optimizing energy efficiency (e.g., using variable frequency drives) and sourcing quality spare parts locally can reduce maintenance costs by up to 18%. Implementing these strategies positions your business to better withstand raw material price volatility and operational uncertainties.

Figure 1: An automated sesame oil pressing equipment configured in a factory optimized for process consistency and maintenance access.

Investing effort in precise machine selection, standardized operation, and diligent maintenance transforms your sesame oil production into a reliable, cost-efficient process delivering consistent high-quality output. Enhance your factory’s productivity and market reputation with expert support tailored to your facility’s unique demands.

Download Your Free Maintenance Checklist PDF Now

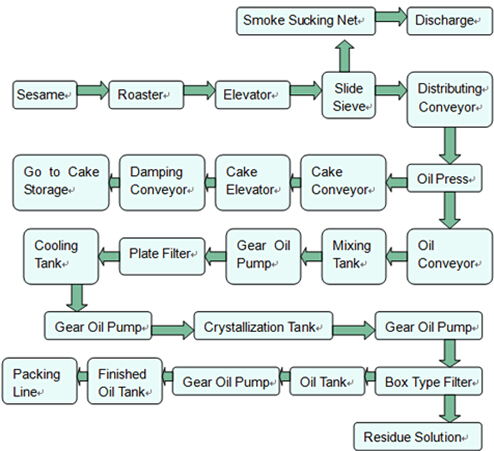

Figure 2: Key operational workflow illustrating critical control points in sesame oil pressing to maximize yield and assure stable product quality.

Schedule a Free Technical Consultation Today

Figure 3: Essential maintenance toolkit enabling factory technicians to perform scheduled servicing and minimize unplanned downtime.