Sesame oil remains a prized ingredient across food, nutraceutical, and cosmetic industries worldwide due to its rich flavor profile and health benefits. Among pressing techniques, hot pressing—which applies controlled heat during extraction—offers increased yield but presents challenges in preserving the oil's nutritional components and delicate aroma. This article explores cutting-edge research focused on optimizing hot-pressing processes to enhance both the quantity and quality of sesame oil, guiding producers to make evidence-based decisions tailored to their production scale and market needs.

Cold pressing mechanically extracts oil under ambient or low temperatures (below 50°C), preserving maximal nutrients and natural aroma but yielding 8-12% less oil. Conversely, hot pressing involves heating sesame seeds between 90°C to 130°C prior to extraction, which softens seed cell walls, boosts yield by 15-20%, but risks nutrient degradation and volatile compound loss if improperly managed.

| Parameter | Cold Pressing | Hot Pressing |

|---|---|---|

| Operating Temperature | ≤ 50°C | 90°C–130°C |

| Oil Yield | ~38-40% | ~44-48% |

| Nutrient Retention | High (Sesamol, Vitamin E preserved) | Moderate (subject to heat management) |

| Aroma Profile | Delicate, natural | Stronger, roasted notes |

Recent studies highlight the importance of exact temperature control and shorter heating duration to mitigate nutritional loss during hot pressing. Maintaining pressing temperature under 120°C and limiting exposure time to under 15 minutes preserves up to 85% of sesamol antioxidants, contrasted with only 60% retention in traditional methods exceeding 130°C for 30 minutes. Furthermore, innovations such as vacuum-assisted hot pressing reduce oxygen exposure, minimizing oxidative degradation.

Controlled heat facilitates enzymatic reactions that develop the characteristic roasted aroma while also enhancing oil extractability by disrupting seed cell matrices. Optimizing this balance between thermal activation and nutrient stability is key: data indicate that adjusting seed conditioning parameters can increase oil yield by 18% while maintaining a Nutra-Score comparable to cold-pressed oil.

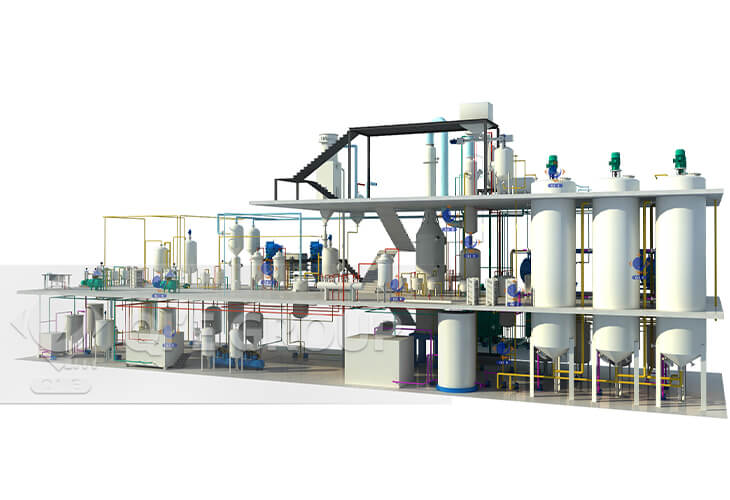

Modern hot-pressing lines integrate automated temperature sensors, real-time viscosity monitoring, and programmable logic controllers (PLCs) to ensure consistent process conditions. For example, programmable screw presses with variable speed settings reduce thermal hotspots, preserving sesame oil’s functional components and aroma volatiles. This not only improves batch-to-batch quality but reduces operator dependence and waste.

These advancements result in heightened production efficiency—up to 25% increase in throughput reported by mid-sized producers adopting the latest hot-pressing automation technologies—while delivering oil with enhanced sensory and health attributes. Consequently, manufacturers serving food-grade sesame oil markets, cosmetic ingredients, and dietary supplements benefit from reduced processing costs and elevated brand reputation.

Small-scale producers focused on premium, cold-pressed oil with maximum nutrition and mild flavor benefit from low-temperature screw presses or traditional hydraulic presses designed for gentle operation, yielding niche market appeal. Medium-to-large manufacturers aiming to balance volume and quality increasingly adopt controlled hot pressing with automation to leverage higher output while respecting product integrity.

| Production Scale | Recommended Technology | Key Benefits |

|---|---|---|

| Small (under 500L/day) | Cold-press screw or hydraulic press | High nutrient retention, premium product |

| Medium (500L–2000L/day) | Automated hot press with temperature control | Balanced yield and quality, lower labor cost |

| Large (2000L+/day) | Industrial-scale automated systems & vacuum hot pressing | Maximized capacity, consistent high-grade oil |

In food manufacturing, improved hot-pressed sesame oil offers richer, fuller aromas that enhance culinary products, from dressings to stir-fry sauces. Nutraceutical and dietary supplement brands benefit from elevated antioxidant content and health claims supported by validated sesamol retention data. Cosmetic formulators prize oils with enhanced aroma and tocopherol preservation for natural skincare formulations that appeal to discerning consumers.

As global demand for functional, naturally-derived ingredients surges, producers well-versed in selecting and implementing scientifically validated hot pressing technologies stand to gain competitive advantage by delivering superior product quality at scale.