For food manufacturers, nutraceutical brands, and cosmetic formulators seeking high-quality sesame oil, understanding the difference between cold-pressing and hot-pressing is no longer optional—it’s essential for product differentiation and compliance with premium market standards.

The core distinction lies in thermal control during extraction:

| Parameter | Cold-Pressed | Hot-Pressed |

|---|---|---|

| Oil Yield (%) | 65–75% | 75–85% |

| Vitamin E Content (mg/100g) | ~10–12 | ~5–7 |

| Flavor Profile | Nutty, aromatic, mild | Roasted, intense, less complex |

If you're targeting premium culinary oils or skincare formulations where purity and nutrition matter most, cold-pressing delivers superior value—even if it means slightly lower yields. For industrial applications like frying or emulsions in cosmetics, hot-pressing offers cost efficiency and consistency.

Recent advancements in multi-stage pressing systems now allow producers to combine both methods: initial cold press for quality, followed by a second stage at moderate heat to maximize yield without sacrificing too much nutrition—a smart middle ground for scaling businesses.

Smart temperature sensors integrated into modern presses can maintain precision within ±2°C, ensuring repeatability across batches—an advantage when entering regulated markets like the EU or North America.

A case study from a mid-sized producer in India showed that switching from single-stage hot pressing to dual-stage cold-hot processing increased their premium segment revenue by 32% over six months—driven by stronger B2B demand from European organic food suppliers.

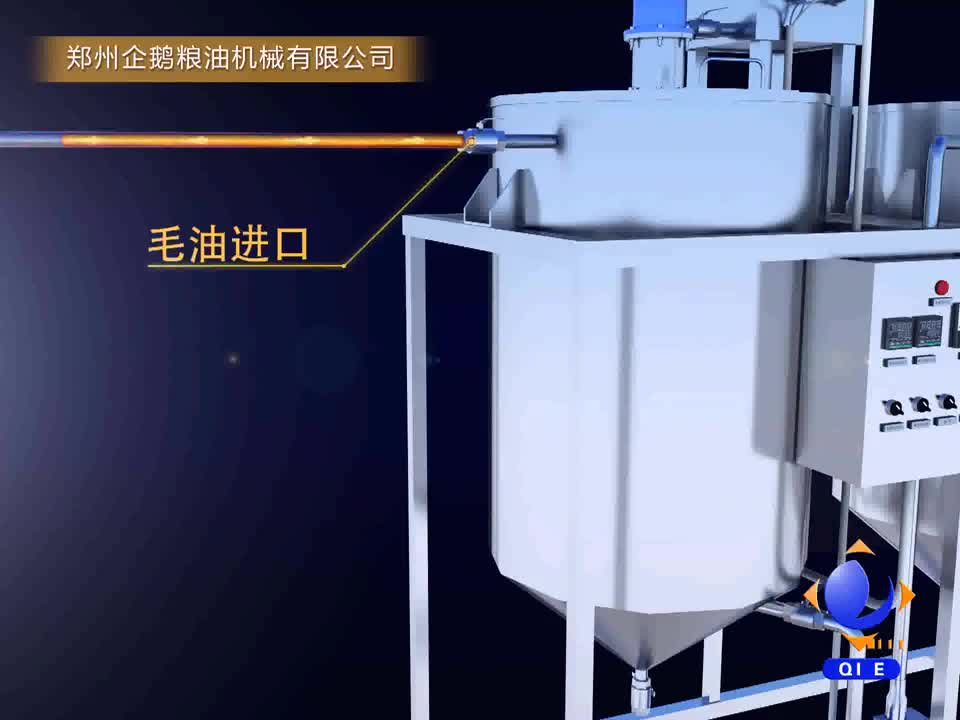

Meanwhile, a large-scale manufacturer in China optimized energy use by upgrading to an electrically heated screw press with real-time feedback loops, reducing power consumption by 18% while maintaining consistent output quality.

Whether you’re setting up a new facility or optimizing existing lines, choosing the right press isn’t just about equipment—it’s about aligning your process with customer expectations, regulatory demands, and profitability goals.

Ready to optimize your sesame oil production? Explore our range of cold-press and hybrid oil extraction systems tailored for food, supplement, and cosmetic industries—engineered for precision, efficiency, and scalability.

Select the Best Press for Your Scale